Categories

- No Air Freight

- Custom Safety Tags

- Flange Management Tags

- TUFFA™ Products – Plastic Tags

- Blank Aluminium & Metal Tags

- Flange Tags

- Recycled / Reclaimed Water Tags

- Shutdown & Turnaround Tags

- Synthetic Safety Tags With Eyelet & Strings

- Aviation Maintenance Tags

- Drill Bit & Drill Rig Tags

- Tags On A Roll

- Scaffolding Safety Tags

- Danger Tags

- Lockout Tags

- Confined Space Tags

- Test and Tag

- Energy Source Tags

- Solar Labels Kit & Battery Engraved Plastic Labels

- Equipment Maintenance & Service Tags

- 5S Tags

- Caution Tags

- Plain Tags

- Self-Locking Tags

- Information Tags

- Hot Work Tags

- Isolation & Commissioning Tags

- Inspection Tags – Sling & Rope, Lifting & Rigging

- Out of Service Tags

- Gas Cylinder Tags

- Repair, Defect & Rework Tags

- Oil, Gas & Energy Tags

- Construction Tags

- Quality Control Tags

- Prohibition Tags

- Mandatory Tags

- Warning Tags

- Asbestos Tags

- Wheel Torque Tags

- Backflow Prevention Tags

- Tag Holders

- Valve Tags: Stainless Steel & Valve Identification Tags

- Cable Ties and Marker Plates

- TUFFA™ Products – Asset Plates

- Lockout Tagout Products

- Permit Stations

- Lockout Padlocks

- Lockout Hasp

- Group Lockout Boxes

- Circuit Breaker Lockouts & Electrical Lockouts

- Cable Lockouts

- Valve Lockouts

- Pneumatic Lockouts

- Lockout Decals

- Lockout Tagout Station

- Blocking Bar Lockout

- Lockout Shadow Boards

- Cylinder Lockout

- Padlock Accessories

- Confined Space & Steering Wheel Control Covers

- Key Cabinets

- Lockout Kits: Personal & Electrical Lockout Kits

- Wirelocks – Car Seal's

- Lockout Bags

- Custom Permit and Lockout Boards

- Prestart and Safety Permit Books

- Signs

- Speed Signs

- Architectural Signs

- Braille Signs

- Biosecurity Signs

- Construction Site Signs

- Caution Signs

- Danger Signs

- Exit / Entry Signs

- Fire Signs

- First Aid Signs

- General Signs

- Hazchem Signs

- Machinery Warning Stickers

- Mandatory Signs

- Class 1 Reflective Mining Signs

- Multi Signs

- Notice Signs

- Pipe Markers

- Prohibition Signs

- Security Signs: Warning & Surveillance Signs

- Swing Stand Signs

- Traffic Signs

- Safety Products

- Security Seals

- Polywoven Strapping

- Underground Class 1 Reflective Tags & Streamers

- Utility Services Standpipe Stickers

- Lead Safety Hooks & Cable Hangers

- Permanent Markers

- HexChex

- Permit Holders / Certificate Holders

- First Aid

- Recreation First Aid Kits

- Survival First Aid Kits

- Compact First Aid Kits

- R1 Vehicle & Marine First Aid Series (1-10 Persons)

- R2 Workplace First Aid Series (1-25 Persons)

- R3 Workplace Pro First Aid Series (1-25 Persons)

- R4 Workplace Medic First Aid Series (1-50 Persons)

- First Aid Books, Manuals & Guides

- Burns and Eye Kits

- Sharps and Biohazard

- Rescue & Emergency

- Barricade Tapes & Chains

- Traffic Cones, Mesh & Road Safety

- Flagging Tape

- SDS & HAZMAT Cabinets

- Height Safety

- Floor & Packaging Tapes

- Safety Mirrors

- Hazardous Spill Control

- Safety Decals

- TUFFA™ Products – PPE

- Synthetic Coated Gloves

- Cut Resistant Gloves

- Welding Eye & Face Protection

- ATG Gloves

- Gumboots

- Respiratory Protection

- Hearing Protection

- Eye Protection

- Welding Gloves

- Safety Hard Hats

- Hi Vis Safety Vests

- Welding Blankets & Apparel

- Knee Protection & Back Support

- PVC Rainsuits

- Disposable Coveralls

- Heat Resistance Gloves

- Chemical Resistant Gloves

- Mechanics Gloves

- Needle Resistant Gloves

- Leather & Cotton Work Gloves Australia

- Disposable Gloves

Lockout Safety Isolation Locks & Isolation Padlocks

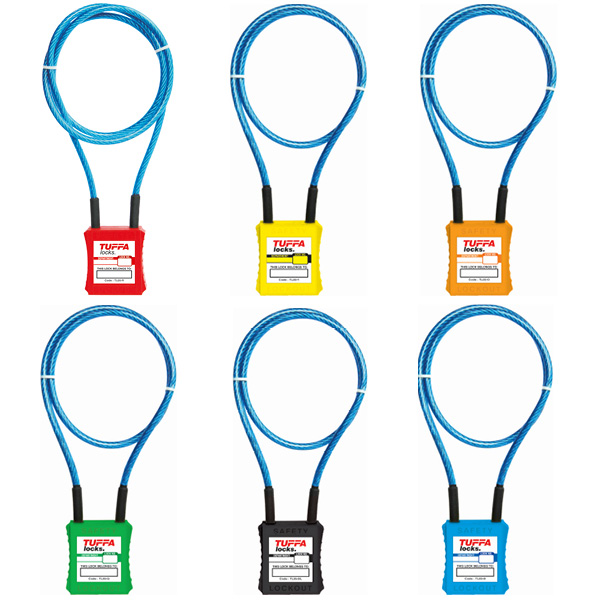

Lockout Padlocks are an essential part of any lockout procedure, the safety integrity starts with the padlock. As specialist supplier of Isolation Padlocks, the TUFFA Lock range comes in Steel shackle, Nylon, Long Shackle, Aluminium Locks. All locks come in both keyed alike and different (sets of 3 right up to sets of 100) comprehensive stock levels and daily shipping Australia wide.

Isolation Locks: A Necessity for Your Lockout Tagout Procedures

Isolation locks, lockout locks or safety lockout padlocks as they are commonly known have a big role in lockout management processes. Their primary purpose is to help prevent accidental startup or usage during the equipment’s maintenance or repair cycle, protecting workers from potential injuries.

Tuffa Products are specialists in the production of Lockout Tagout Equipment for mining, oil, gas and the energy market. Their range includes lockout devices, padlocks, kits, tags and hasps, lockout boxes, permit stations, circuit breaker lockouts and more. These high-quality products are made from durable materials that can withstand harsh environments.

The Importance in Industrial Settings

In industrial environments, isolation padlocks play a critical role from various perspectives including:

- Protecting the workforce against accidental/unexpected start-up of equipment

- Neutralising energy sources (electrical, hydraulic, pneumatic, or chemical) to protect equipment from damage

- Remaining compliant with safety standards and regulations

- Following effective Lockout Tagout procedures that align with industry best practices

- Ensuring operations are not interrupted with timely maintenance activities to avoid prolonged downtimes

- Preventing lawsuits, compensation claims, and increased insurance premiums by following proper safety procedures

The application process for an isolation lock includes :

- Identifying all power sources associated with the machine

- Deactivating identified power sources

- Locking out energy-isolating devices using safety lockout padlocks

- Verifying and testing the energy source isolated

- Once repairs are complete, ensure the machine is safe to use

- Removing the padlock and reactivating the energy source

Key Attributes

Isolation locks are specialised padlocks used in lockout tagout processes. With effective use, they promote a safe working culture. Here are a few features that contribute to its effectiveness:

- Durability: Made of durable materials that are non-conductive and corrosion-resistant like nylon or reinforced plastic, these locks can withstand harsh environments and are safe to use even under heavy chemical or physical conditions.

- Tamper Resistance: With features like reinforced shackles and different locking mechanisms, the padlocks can be tamper-proof.

- Colour Coding: By using highly visible and bright colours, the locks can be recognisable even from distances. It can also help identify specific personnel, department or types of maintenance activities.

- Clear Visibility: By providing labels on the padlock, essential information like the user’s name, contact details and the purpose of the lockout can be accessed and monitored. It also helps reduce the risk of unauthorised removal.

- Keying Options: Our locks have different keying options available such as keyed-alike, keyed-different, and master-keyed systems. Companies can choose their keying systems on the level of control and security required.

Applications

In industrial and commercial settings, several types of equipment require the use of isolation padlocks during servicing operations to promote a safe working environment. The types of equipment that commonly need isolation are:

- Electrical equipment like circuit breakers, transformers, control panels and high-voltage switchgear

- Production equipment such as conveyor systems, presses and stamping machines, milling machines and robotic arms

- Pneumatic or hydraulic equipment like valves, compressors, pumps and cylinders

- Flow control devices, water or gas supply systems and reactors in chemical and utility plants

- Lifting equipment like cranes, elevators and lifts

- Energy generation equipment such as generators, solar panels and wind turbines

Tips for Effective Use

- Follow Lockout/Tagout Procedures: Before using locks, make sure the workforce understands and follows company lockout tagout procedures. Designing a guided training course can help all personnel involved in lockout tagout processes understand the importance of lockout safety and how to use these locks correctly.

- Perform risk assessment: Conduct a thorough assessment to identify potential hazards and determine ideal lockout activities

- Choose the right padlock: Consider factors like environment, type of equipment and security to help you select the right padlock.

- Use lockout hasps: With multiple people working on the same equipment, lockout hasps help create a secure point for each worker’s padlock.

- Padlock placement: Place padlocks in a visible and accessible location to ensure communication that the equipment is locked out. This also helps prevent unauthorised removal.

- Regular inspections: Conduct frequent inspections to ensure the isolated locks padlocks are free from damage, functioning properly and require replacement if necessary.

- Secure key control: Keep keys accessible only to authorised people.

- Emergency preparedness: In urgent situations, have a clear plan for handling emergencies and make sure everyone knows how to remove padlocks quickly.

- Documentation: Maintain detailed records of lockout tagout processes to track compliance and identify areas of improvement.

Where to Buy Lockout Tagout Products

Effective use of Lockout Locks can enhance workplace safety and help prevent accidents where heavy machinery and complex equipment are used. Tuffa Products offer a range of Locks that can be utilised and incorporated into your company’s Lockout Tagout procedures.

We design and manufacture a range of safety lockout padlocks with reinforced nylon bodies and a choice of steel, cable, nylon or aluminium shackles. All products are 100% Australian Made and we offer fast and reliable delivery across the country.

To order online, browse our expansive range of products and choose the padlock that is right for your facility. You can also contact us if you need any help or advice on the right lock for your workplace.